The utility model

ABS Anti-Lock Braking is the abbreviation of the System, it is the electronic system during braking control and monitor the speed of vehicles. It is through the conventional braking system play a role, can improve the vehicle active safety. The failure of ABS, the conventional braking system still functions. The ABS system mainly includes several parts ECU, ABS solenoid valve, wheel speed sensor and wiring harness.

In emergency braking to maintain vehicle direction maneuverability;

Shorten and optimize the braking distance. On the road with low adhesion, braking distance shortened by more than 10%, keep the optimal road adhesion coefficient utilization - namely the best braking distance.

To reduce the traffic accident.

Reduce the driver mental burden.

Reduce tire wear and repair costs.

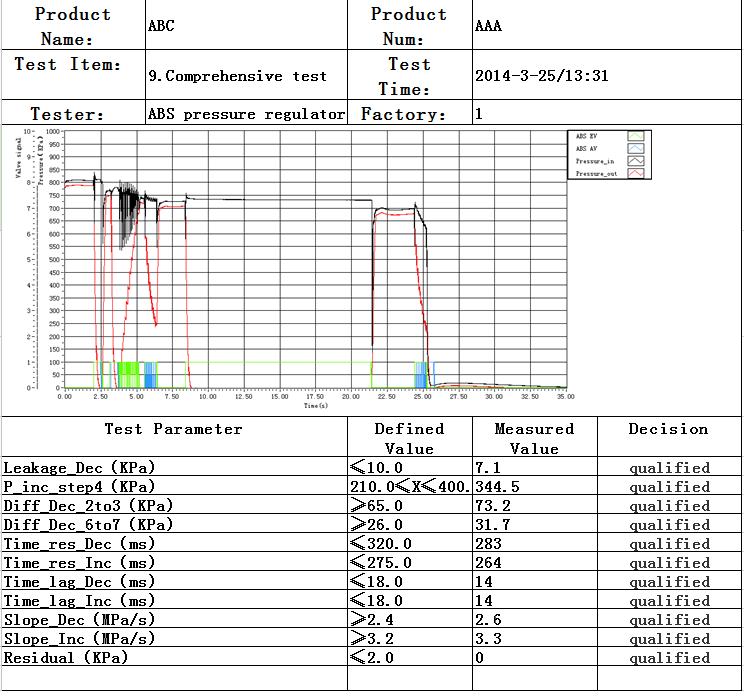

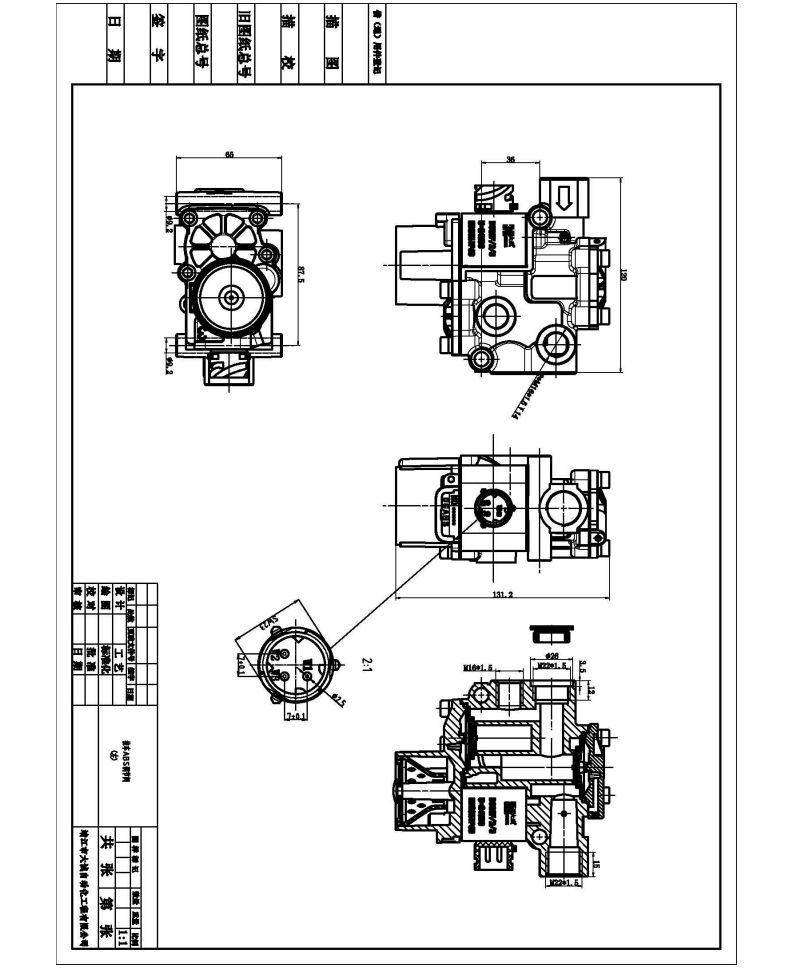

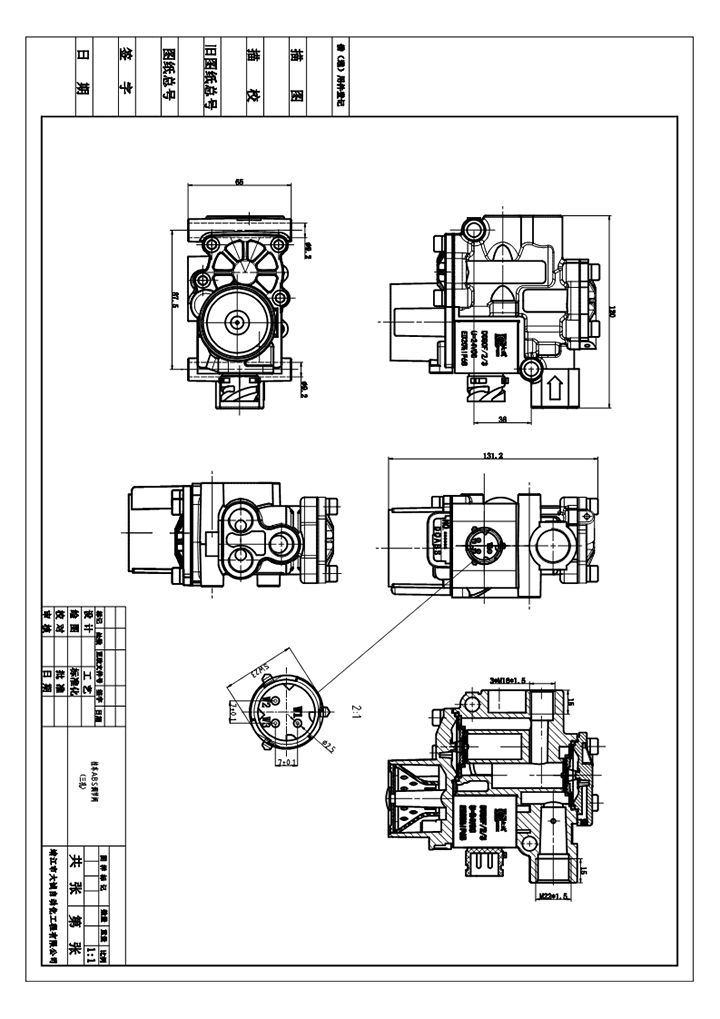

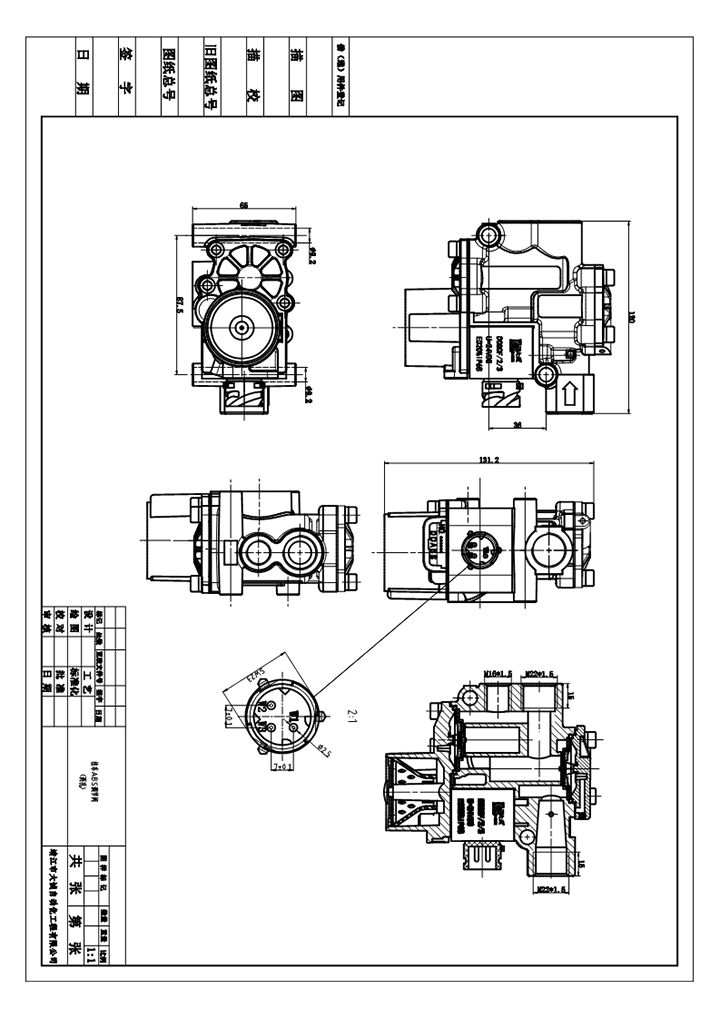

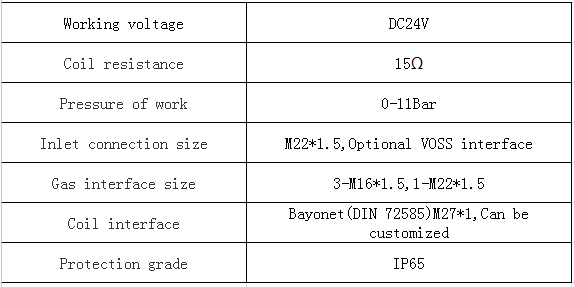

ABS solenoid valve is one of the main executive component of the ABS system, which receives signals from the ECU to the brake chamber for pneumatic, exhaust and holding pressure. Compared with ordinary ABS solenoid valve, Trailer ABS solenoid valve flow more, a solenoid valve can control up to three brake chamber and the gas, so relative to conventional ABS solenoid valve, solenoid valve installed Trailer ABS cost advantage is very obvious.

Trailer ABS solenoid valve in our company listed in 2009, after continuous test in 5 years and perfect, at present already setting. In order to facilitate the installation, we have developed two different direction of the electromagnetic valve, when installed, the electromagnetic valve can be on both sides of the brake chamber are respectively arranged in two directions, need not transfer elbow, very convenient.

"Electromagnetic air regulator for automobile anti lock braking system performance requirements and bench test methods" draft.