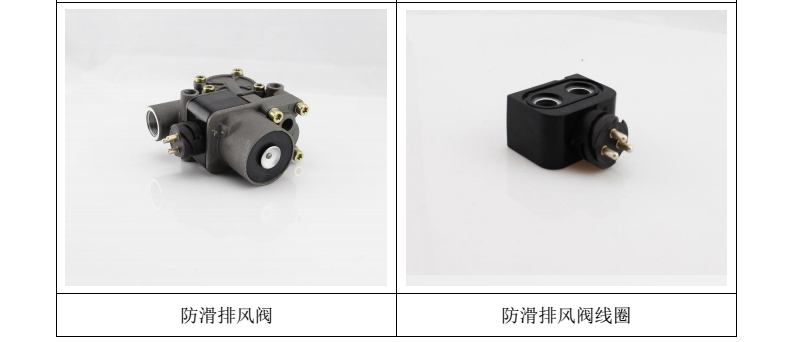

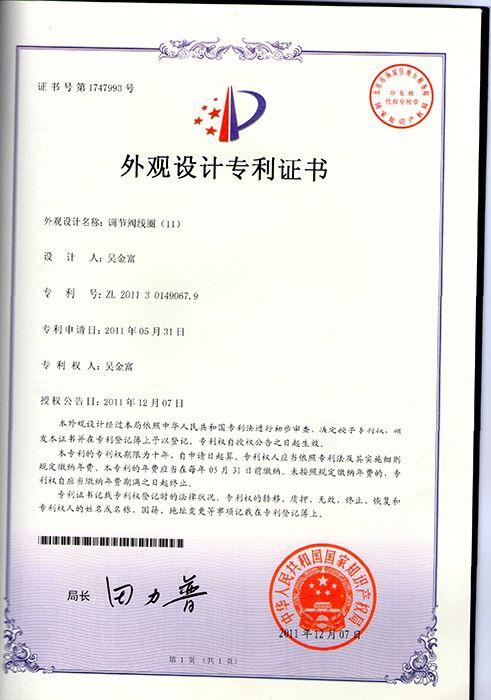

Appearance design

When the train brakes, the brake shoe or the brake disc generates braking force to slow down the train by the power between wheels, if the braking force is too much or low adhesion wheel-rail, the wheels will be locked and glided. The gliding will reduce the braking force, exceed the braking distance, bruise wheels, thus affecting the movement of the train. When the train speeds up, especially the passengers train speeds up, in order to shorten the braking distance, the train must make full use of the adhesive force. As to prevent the gliding, it is necessary to install anti-slip system.

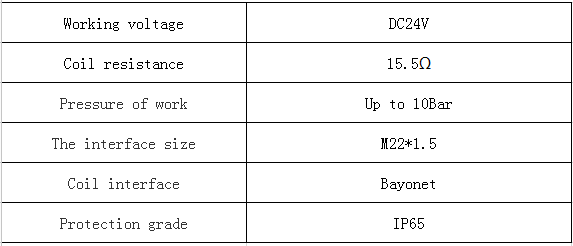

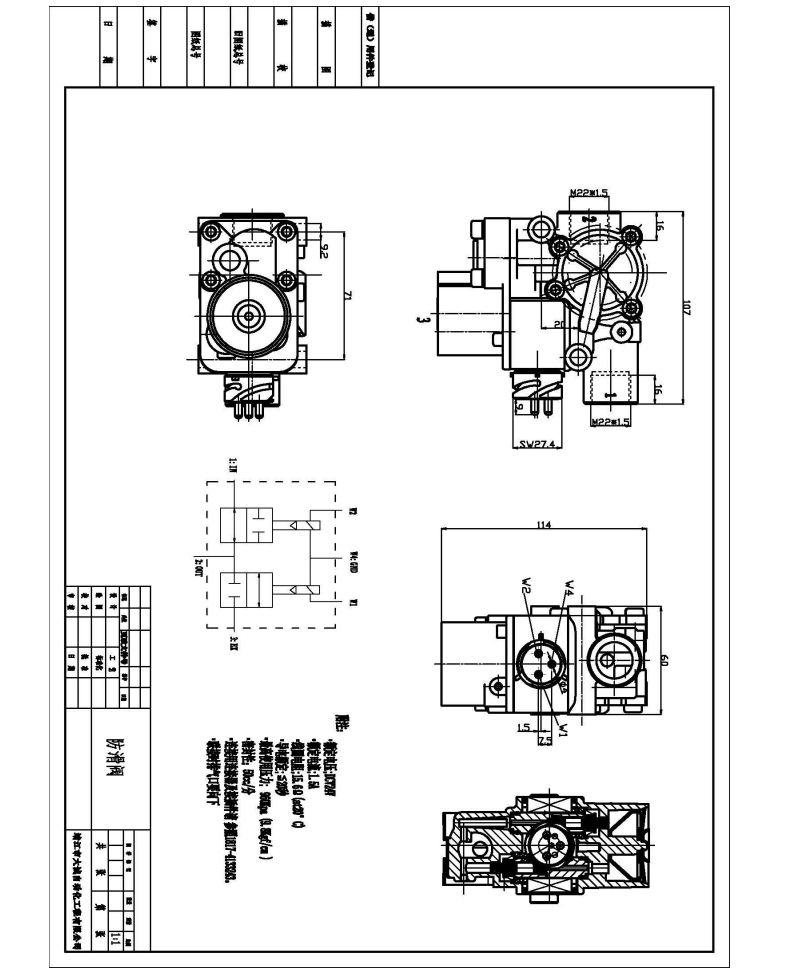

Anti-slip system consists of wheel-speed sensors, ECU, anti-slip valve and pressure switch etc. When the ECU gets signal of locking-gliding from one of the wheels, it will send relevant signal to the anti-slip valve in this axle, then the anti-slip valve exhausting air and the braking cylinder reducing pressure to force the axle to speed up again, avoiding gliding.

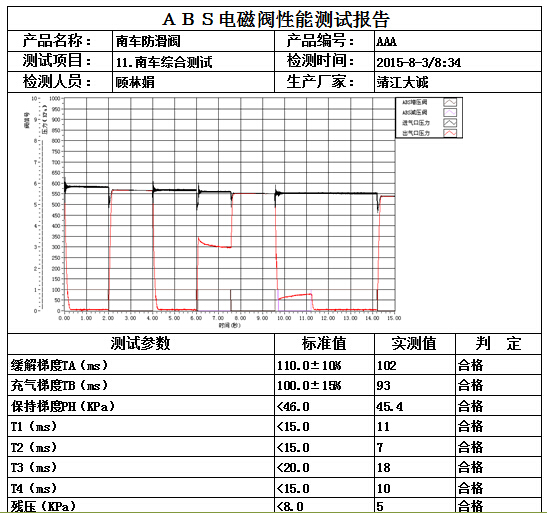

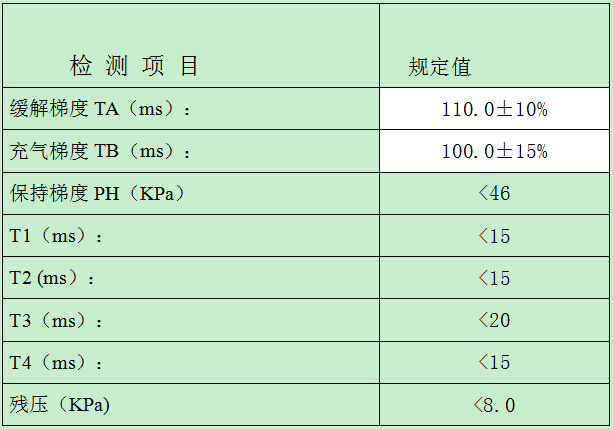

Our company was developed on 2010 with Nanjing Puzhen Vehicle Co., Ltd. We have already finished the testing of high-low temperature, salt fog, vibration, functioning, all the testing reaches the required standard. It will be put into production soon.