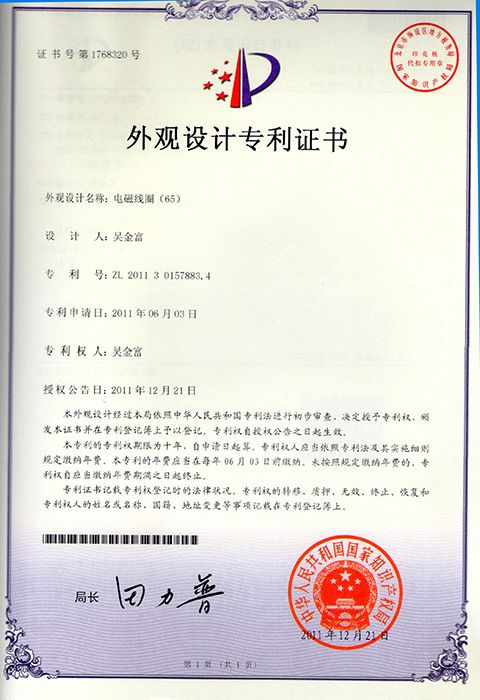

Appearance design

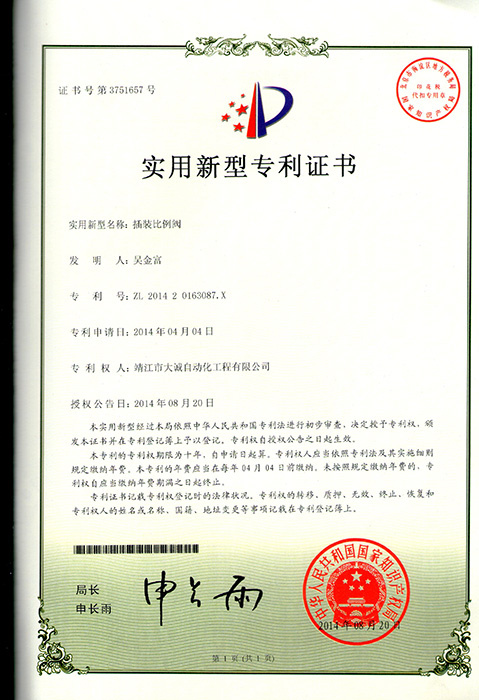

The utility model

ABS is Anti-Lock Braking System, which is an electronic system controlling and monitoring speed of vehicles during the air brake period. It works in a normal air brake system to improve the vehicle active safety. If ABS loses its function, the normal air brake system still works. The ABS mainly includes ECU, ABS solenoid valve, wheel speed sensor and cables.

In emergency braking to maintain vehicle direction maneuverability; shorten and optimize the braking distance. On the road with low adhesion, it reduces the braking distance more than 10%; in the normal road, it keeps the optimal road adhesion coefficient utilization - the best braking distance. To reduce the traffic accidents, driver’s mental burden and the tire maintenance costs.

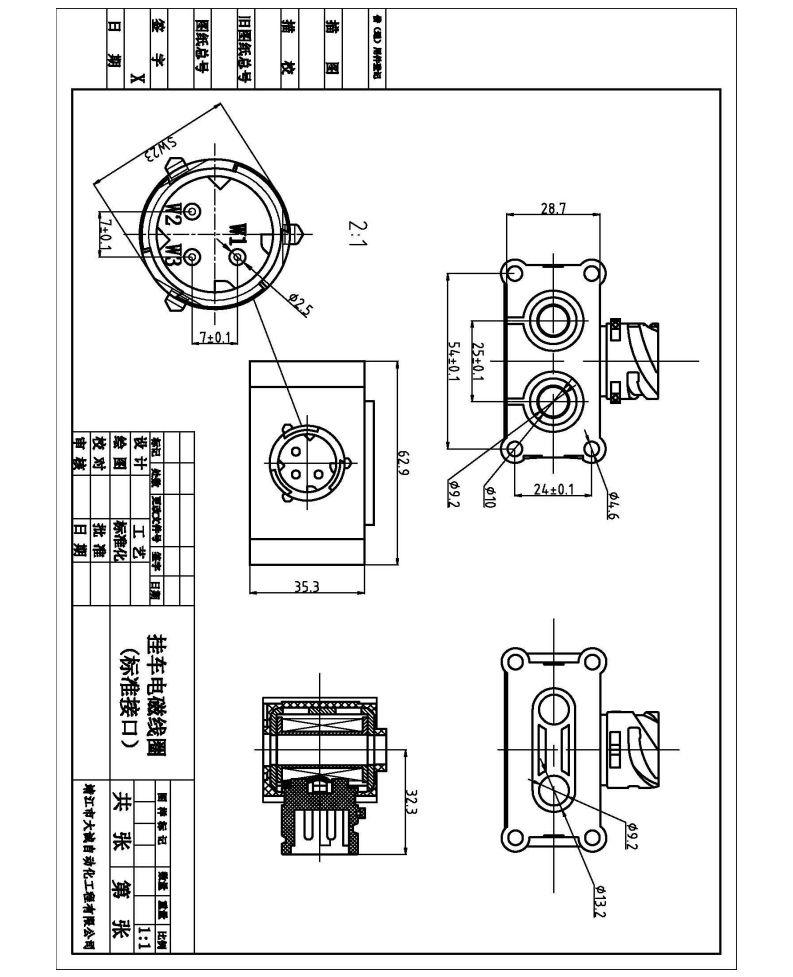

ABS relay valve is main executive component of the ABS system, it receives signals from the ECU to pneumatic, exhaust and hold pressure for brake chamber. Compared with ordinary ABS solenoid valve, Trailer ABS relay valve has more rate of flow, which can control three brake chamber for air supply, so to ABS solenoid valve, installing Trailer ABS relay valve is more economical and functional.

My company's Trailer ABS relay valve was put into market on 2005, through continuous testing and improvement, product’s performance is stable, the annual output reaches up to 20,000pcs.

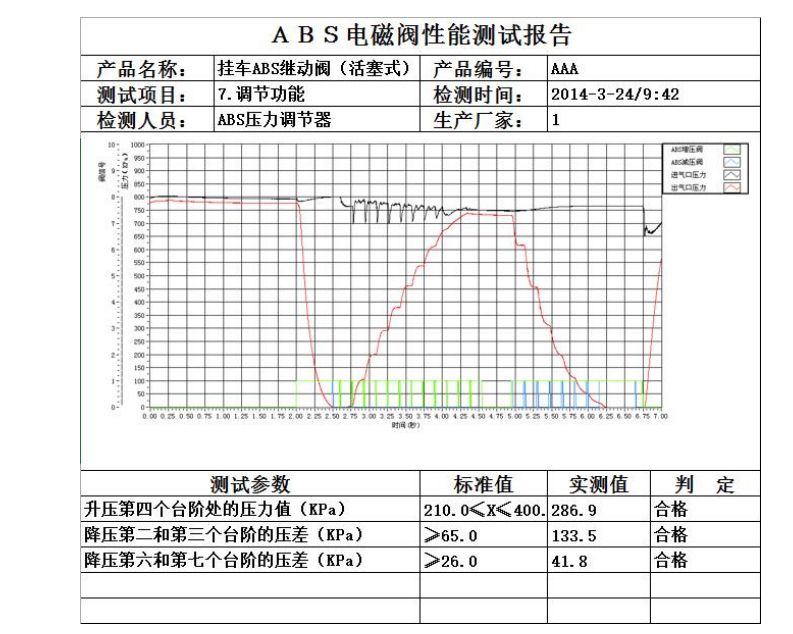

"Electromagnetic air regulator for automobile anti lock braking system performance requirements and bench test methods" draft.